Dreaming of push-button starts and the confidence to call the shots?

Intro to design places you in the driver's seat as I guide you through the foolproof process for professional hydraulic designs THAT WORK.

Trusted by Companies Like:

Introducing Your Mentor Kyle Probert

Kyle Probert is an expert in hydraulics and fluid power and a recognised CMSE Certified Machinery Safety Expert through TUN Nord. With extensive experience in training teams from beginner certifications to advanced diplomas and continued guidance through mentorship for other fluid power engineers, Kyle brings a wealth of knowledge to the Introduction To Fluid Power Course. His proficiency extends to creating more efficient, custom solutions and troubleshooting incidents to improve overall system performance.

Recently Kyle has noticed a widening gap emerging in the hydraulics industry, especially when it comes to design and advanced troubleshooting. He is committed to filling that gap, serving as a mentor to help others design and validate new concepts with confidence and ease.

Kyle’s journey began like many others as an apprentice. Often left with downtime, he took advantage of the opportunity to learn additional skills outside the regular scope of fluid power mechanics. This proactive approach helped him understand how each component contributes to a system's optimal function. He also seized every chance to learn from visiting technical experts, expanding his knowledge and breaking the monotony of his apprenticeship.

These formative experiences equipped Kyle with the expertise necessary for large-scale custom projects, from designing specialised hydraulic fittings to developing entirely new hydraulic solutions. His innovative approach and dedication to continuous learning have set him apart in the industry.

Kyle is passionate about sharing his knowledge and experiences, aiming to empower others in the hydraulics field. By providing mentorship and guidance, he helps professionals like-you achieve their goals and gain confidence in their design skills.

Introducing Your Mentor

Kyle Probert

Kyle Probert is an expert in hydraulics and fluid power and a recognised CMSE Certified Machinery Safety Expert through TUN Nord. With extensive experience in training teams from beginner certifications to advanced diplomas and continued guidance through mentorship for other fluid power engineers, Kyle brings a wealth of knowledge to the Introduction To Fluid Power Course. His proficiency extends to creating more efficient, custom solutions and troubleshooting incidents to improve overall system performance.

Recently Kyle has noticed a widening gap emerging in the hydraulics industry, especially when it comes to design and advanced troubleshooting. He is committed to filling that gap, serving as a mentor to help others design and validate new concepts with confidence and ease.

Kyle’s journey began like many others as an apprentice. Often left with downtime, he took advantage of the opportunity to learn additional skills outside the regular scope of fluid power mechanics. This proactive approach helped him understand how each component contributes to a system's optimal function. He also seized every chance to learn from visiting technical experts, expanding his knowledge and breaking the monotony of his apprenticeship.

These formative experiences equipped Kyle with the expertise necessary for large-scale custom projects, from designing specialised hydraulic fittings to developing entirely new hydraulic solutions. His innovative approach and dedication to continuous learning have set him apart in the industry.

Kyle is passionate about sharing his knowledge and experiences, aiming to empower others in the hydraulics field. By providing mentorship and guidance, he helps professionals like-you achieve their goals and gain confidence in their design skills.

Let's get real for

a minute.

Let's get real for

a minute.

You aren’t an apprentice anymore. You’ve worked hard to get to where you are in your career.

You have the knowledge, you have the skills, and you have the hands-on experience.

But in working your way through your career you’ve found yourself in a position where you are required to design and optimise hydraulic systems.

Now designing systems is its own skill. But because you have all the knowledge you were expected to perform from day 1. But now you find yourself troubleshooting problems you didn’t even know existed until suddenly they happened with the new system you were building.

You aren’t an apprentice anymore. You’ve worked hard to get to where you are in your career.

You have the knowledge, you have the skills, and you have the hands-on experience.

But in working your way through your career you’ve found yourself in a position where you are required to design and optimise hydraulic systems.

Now designing systems is its own skill. But because you have all the knowledge you were expected to perform from day 1. But now you find yourself troubleshooting problems you didn’t even know existed until suddenly they happened with the new system you were building.

With a skills gap emerging in our industry it can also be difficult to find people who have the skills to help you. It could be causing you stress at work, or you might’ve lost confidence and be wondering if you’re the right person for the job.

I want to reassure you that it’s normal to not know what to do when you first start working in design. I mean you wouldn’t expect anyone else to smash something for the first time if they’d never done it before?

But how can we get you to a place where you are confident, competent, have a process for design and nail that push-button start every time?

Let me introduce you to our Introduction to Fluid Power Design Course.

With a skills gap emerging in our industry it can also be difficult to find people who have the skills to help you. It could be causing you stress at work, or you might’ve lost confidence and be wondering if you’re the right person for the job.

I want to reassure you that it’s normal to not know what to do when you first start working in design. I mean you wouldn’t expect anyone else to smash something for the first time if they’d never done it before?

But how can we get you to a place where you are confident, competent, have a process for design and nail that push-button start every time?

Let me introduce you to our Introduction to Fluid Power Design Course.

A Quick Snapshot

Guided program breaking down everything you need to know about Fluid Power Design to go from beginner to understanding & building better systems in just 9 sessions.

A Quick Snapshot

Guided program breaking down everything you need to know about Fluid Power Design to go from beginner to understanding & building better systems in just 9 sessions.

Timeframe

12 weeks recommended (however, the coursework is entirely self-paced so take as much time as you need to fully understand the concepts)

Delivery

Online Tutorials (recorded and loaded into our platform so you can review the content as much as you need)

Assessment

Projects + Practical designs based on the systems that you currently use Investment

End Result

The ability to design basic fluid power systems and create safer and more efficient systems to be used on your worksite. More confidence in your ability to create working designs, with a push button start, even without another set of eyes looking over your work because you've been made aware of the possible pitfalls of designs and all the most important info to create designs that not only work but are the best solution to your problem.

Timeframe

12 weeks recommended (however, the coursework is entirely self-paced so take as much time as you need to fully understand the concepts)

Delivery

Online Tutorials (recorded and loaded into our platform so you can review the content as much as you need)

Assessment

Projects + Practical designs based on the systems that you currently use Investment

End Result

The ability to design basic fluid power systems and create safer and more efficient systems to be used on your worksite. More confidence in your ability to create working designs, with a push button start, even without another set of eyes looking over your work because you've been made aware of the possible pitfalls of designs and all the most important info to create designs that not only work but are the best solution to your problem.

How Will it Work?

How Will it Work?

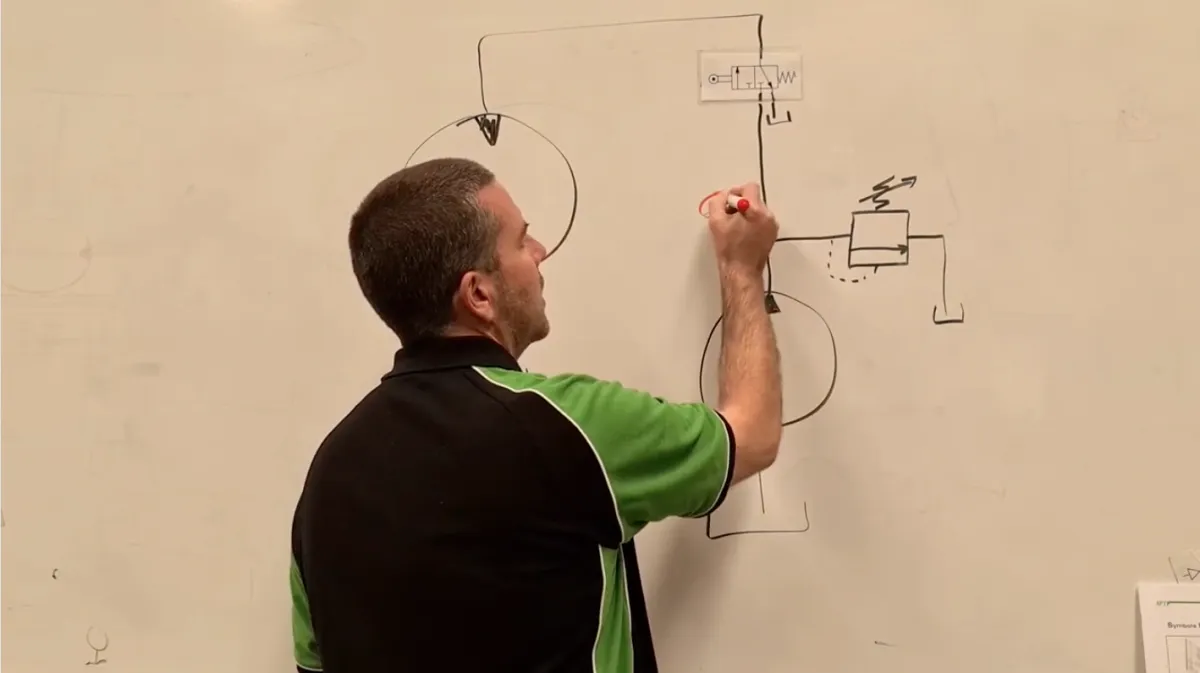

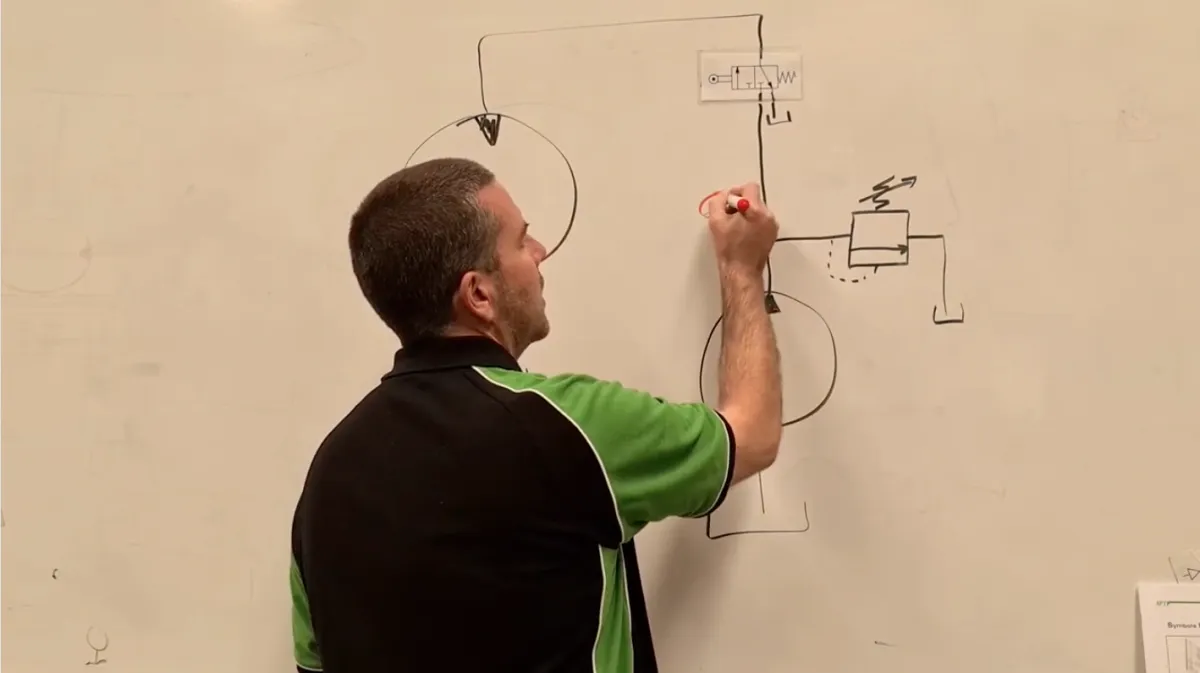

"Hydraulic System Design Course for Engineers and Technicians"

This course will be helping engineers, workshop managers and technical assistants who want to gain further knowledge and confidence in how to design hydraulic systems to best suit their work environment now and into the future. With lots happening in the hydraulics industry and the need to keep up with advancing technologies, we’ll run through both design basics and cover topics that will help you design something more sophisticated in the future, but for now let’s keep it simple.

"Interactive Hydraulic Design Modules with Expert Guidance"

Each online module will be led by hydraulicSub-Headlines expert Kyle Probert and while working through each topic you will be given an activity or project that will help you process what you’ve learned so that you can apply it to the current project you are working on. The modules are laid out in a way that walks you through the process of designing each element required for a fully functional system. Once you’ve completed the activity you can then drop your finished element into the group for feedback so not only are you taking this opportunity to learn but also to use your expertise to help others.

"Hands-On Hydraulic Design: Overcome Obstacles and Gain Confidence"

The biggest focus is on the actual design process itself and how we work through any obstacles that present themselves. So, if you want to gain the confidence and competence you need to make design decisions, to troubleshoot problems, and create custom solutions then you’re in the right place! There is nothing else like this course available in Australia.

"Hydraulic System Design Course for Engineers and Technicians"

This course will be helping engineers, workshop managers and technical assistants who want to gain further knowledge and confidence in how to design hydraulic systems to best suit their work environment now and into the future. With lots happening in the hydraulics industry and the need to keep up with advancing technologies, we’ll run through both design basics and cover topics that will help you design something more sophisticated in the future, but for now let’s keep it simple.

"Interactive Hydraulic Design Modules with Expert Guidance"

Each online module will be led by hydraulicSub-Headlines expert Kyle Probert and while working through each topic you will be given an activity or project that will help you process what you’ve learned so that you can apply it to the current project you are working on. The modules are laid out in a way that walks you through the process of designing each element required for a fully functional system. Once you’ve completed the activity you can then drop your finished element into the group for feedback so not only are you taking this opportunity to learn but also to use your expertise to help others.

"Hands-On Hydraulic Design: Overcome Obstacles and Gain Confidence"

The biggest focus is on the actual design process itself and how we work through any obstacles that present themselves. So, if you want to gain the confidence and competence you need to make design decisions, to troubleshoot problems, and create custom solutions then you’re in the right place! There is nothing else like this course available in Australia.

Who Is It For?

This is not a beginner friendly course and it is highly recommended that participants have experience working with hydraulics systems and are familiar with basic engineering concepts.

Common roles that would benefit from this course are hydraulic engineers, workshop managers, technical assistants, and others who regularly are required to design or optimise hydraulic systems in their work.

*This is not a nationally accredited course

Who Is It For?

This is not a beginner friendly course and it is highly recommended that participants have experience working with hydraulics systems and are familiar with basic engineering concepts.

Common roles that would benefit from this course are hydraulic engineers, workshop managers, technical assistants, and others who regularly are required to design or optimise hydraulic systems in their work.

*This is not a nationally accredited course

Money-Back Guarantee

If you get stuck into the course and within 48 hours have decided that this isn't right for you, we'll give you your money back no questions asked. However, we do require that you at least complete the first 2 sessions within module 1 before you make your decision.

Money-Back Guarantee

If you get stuck into the course and within 48 hours have decided that this isn't right for you, we'll give you your money back no questions asked. However, we do require that you at least complete the first 2 sessions within module 1 before you make your decision.

Modules

With over 33 recorded tutorials that you can watch again and again as you work through this process there is a lot to learn, but let me break it down into 5 main topics for you.

Modules

With over 33 recorded tutorials that you can watch again and again as you work through this process there is a lot to learn, but let me break it down into 5 main topics for you.

TOPIC 1: Engineering in Fluid Power Design

This will be a quick refresher of some of your basic engineering principles, but specifically how they apply in the world of hydraulics. Sometimes even when we know what we’re doing, it can be scary to apply in unfamiliar contexts, this module will get you up to speed so that you feel ready to tackle your design project.

TOPIC 2: Intro to design process (symbols & basic components)

This is where we’ll be covering the basics and working through the exact process you should follow every time you work on a design project to ensure you have a push button start, and smooth sailing from ideation to finished product. This will include looking at symbols and schematics, working with design templates, and looking at how you might use specific hydraulic components in your designs. Whether we’re talking about actuators, or pumps and tanks, this topic will get you feeling confident in your design choices.

TOPIC 3: Valves

Topic three is a deep dive into valves. Whether you are looking at PCVs, DCVs, or FCVs, this topic breaks down each of these components and walks you through what considerations you will need to make when including them in your design. We’ll be looking at flow control and making sure that everything is set in your system so that we don’t have failure to launch!

TOPIC 4: Hoses & Pipes

Your design needs something to connect it all together and choosing the right hose can make all of the difference. This is our last component based topic and will see you making the design choices you need to get your system operational. We’ll talk through the potential pitfalls of different choices so that you can make a decision that is best for your end product.

TOPIC 5: The Final Design And Troubleshooting

We’ll be putting pen to paper and creating the schematics of your final design in these sessions. But what if after all of this work you still run into a problem? Even the most experienced hydraulics professionals can make mistakes and that is why it is important to understand the role of troubleshooting in the design process. We’ll work on troubleshooting any problems that you come across so that you can tackle them early and still have that push-button start that you’ve always dreamed of.

TOPIC 1: Engineering in Fluid Power Design

This will be a quick refresher of some of your basic engineering principles, but specifically how they apply in the world of hydraulics. Sometimes even when we know what we’re doing, it can be scary to apply in unfamiliar contexts, this module will get you up to speed so that you feel ready to tackle your design project.

TOPIC 2: Intro to design process (symbols and basic components)

This is where we’ll be covering the basics and working through the exact process you should follow every time you work on a design project to ensure you have a push button start, and smooth sailing from ideation to finished product. This will include looking at symbols and schematics, working with design templates, and looking at how you might use specific hydraulic components in your designs. Whether we’re talking about actuators, or pumps and tanks, this topic will get you feeling confident in your design choices.

TOPIC 3: Valves

Topic three is a deep dive into valves. Whether you are looking at PCVs, DCVs, or FCVs, this topic breaks down each of these components and walks you through what considerations you will need to make when including them in your design. We’ll be looking at flow control and making sure that everything is set in your system so that we don’t have failure to launch!

TOPIC 4: Hoses & Pipes

Your design needs something to connect it all together and choosing the right hose can make all of the difference. This is our last component based topic and will see you making the design choices you need to get your system operational. We’ll talk through the potential pitfalls of different choices so that you can make a decision that is best for your end product.

sdag

TOPIC 4: Hoses & Pipes

Your design needs something to connect it all together and choosing the right hose can make all of the difference. This is our last component based topic and will see you making the design choices you need to get your system operational. We’ll talk through the potential pitfalls of different choices so that you can make a decision that is best for your end product.

TOPIC 5: The Final Design And Troubleshooting

We’ll be putting pen to paper and creating the schematics of your final design in these sessions. But what if after all of this work you still run into a problem? Even the most experienced hydraulics professionals can make mistakes and that is why it is important to understand the role of troubleshooting in the design process. We’ll work on troubleshooting any problems that you come across so that you can tackle them early and still have that push-button start that you’ve always dreamed of.

TOPIC 5: The Final Design And Troubleshooting

We’ll be putting pen to paper and creating the schematics of your final design in these sessions. But what if after all of this work you still run into a problem? Even the most experienced hydraulics professionals can make mistakes and that is why it is important to understand the role of troubleshooting in the design process. We’ll work on troubleshooting any problems that you come across so that you can tackle them early and still have that push-button start that you’ve always dreamed of.

What you will get with the Intro to Fluid Power Design (BONUSES)

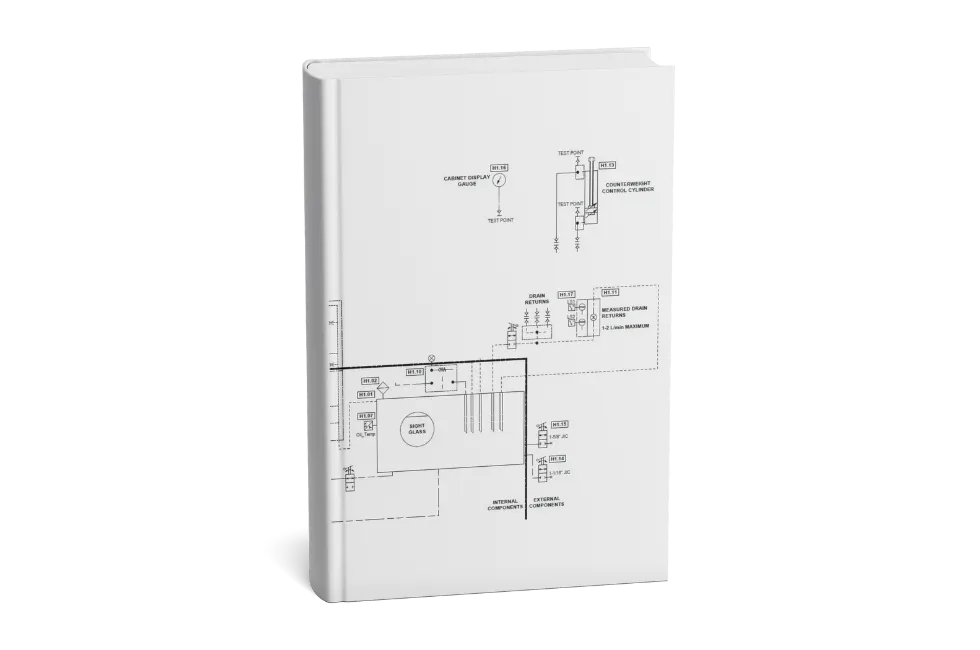

Fast Track Symbols Book ($2000)

A visual guide on how to draw schematics so you can quickly put together system drawings.

Hydraulic System Design Scope

Use this template to scope out all variables at the start of your hydraulic design project. It helps you gather information quickly, allowing for confident early decisions.

Engineer’s Cheat Sheet ($1000)

Easy access to every formula you need to understand hydraulic systems.

Exclusive Engineering Community ($1200)

Learn and improve alongside other students in a Community Group.

Safety and Awareness Training ($2000)

Learn and improve alongside other students in a Community Group.

Fast Track Symbols Book ($2000)

A visual guide on how to draw schematics so you can quickly put together system drawings.

Hydraulic System Design Scope

Use this template to scope out all variables at the start of your hydraulic design project. It helps you gather information quickly, allowing for confident early decisions.

Engineer’s Cheat Sheet ($1000)

Easy access to every formula you need to understand hydraulic systems.

Exclusive Engineering Community ($1200)

Learn and improve alongside other students in a Community Group.