Master Fluid Power Design:

From Sketch to System

Transform your approach to hydraulic systems with our proven design template - gain the confidence to design, optimize, and document systems that work exactly as intended

15+ years Industry Experience

Industry-active expertise

Trusted by:

Master international schematic standards

Learn proper system documentation

Gain confidence in component selection

Create efficient, safe designs

Struggling with Hydraulic System Design?

You're Not Alone

Are you...

Copying existing designs without fully understanding why they work?

Worried about making costly mistakes in system specifications?

Finding it hard to document your practical knowledge properly?

Needing to validate your experience with proper design principles?

Are you...

Having trouble translating theoretical knowledge into practical solutions?

Uncertain about optimal component selection and sizing?

Struggling to create efficient, maintainable systems?

Looking to bridge the gap between calculations and real-world application?

Without a proper design template and methodology, you might be:

Overengineering systems due to uncertainty

Missing critical safety considerations

Creating documentation that's hard to follow

Losing time and money on inefficient designs

There's a better way to approach hydraulic system design - one that combines practical application with proven templates and safety standards.

Introducing Your Mentor Kyle Probert

Kyle Probert is an expert in hydraulics and fluid power and a recognised CMSE Certified Machinery Safety Expert through TUN Nord. With extensive experience in training teams from beginner certifications to advanced diplomas and continued guidance through mentorship for other fluid power engineers, Kyle brings a wealth of knowledge to the Introduction To Fluid Power Course. His proficiency extends to creating more efficient, custom solutions and troubleshooting incidents to improve overall system performance.

Recently Kyle has noticed a widening gap emerging in the hydraulics industry, especially when it comes to design and advanced troubleshooting. He is committed to filling that gap, serving as a mentor to help others design and validate new concepts with confidence and ease.

Kyle’s journey began like many others as an apprentice. Often left with downtime, he took advantage of the opportunity to learn additional skills outside the regular scope of fluid power mechanics. This proactive approach helped him understand how each component contributes to a system's optimal function. He also seized every chance to learn from visiting technical experts, expanding his knowledge and breaking the monotony of his apprenticeship.

These formative experiences equipped Kyle with the expertise necessary for large-scale custom projects, from designing specialised hydraulic fittings to developing entirely new hydraulic solutions. His innovative approach and dedication to continuous learning have set him apart in the industry.

Kyle is passionate about sharing his knowledge and experiences, aiming to empower others in the hydraulics field. By providing mentorship and guidance, he helps professionals like-you achieve their goals and gain confidence in their design skills.

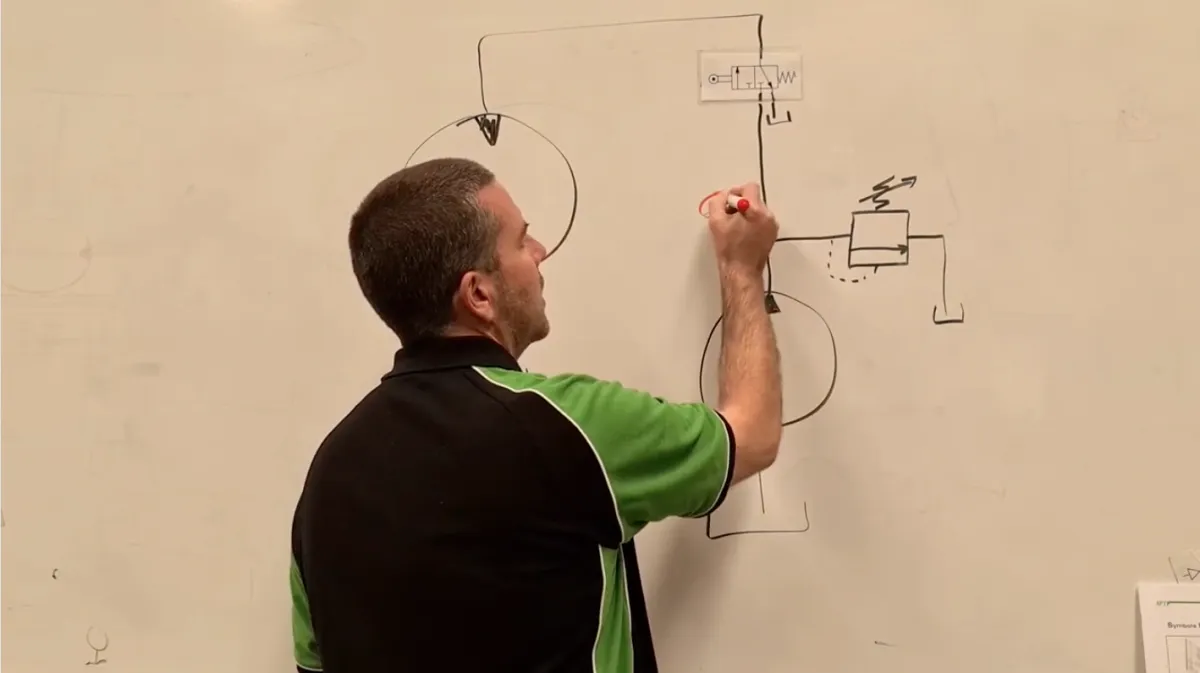

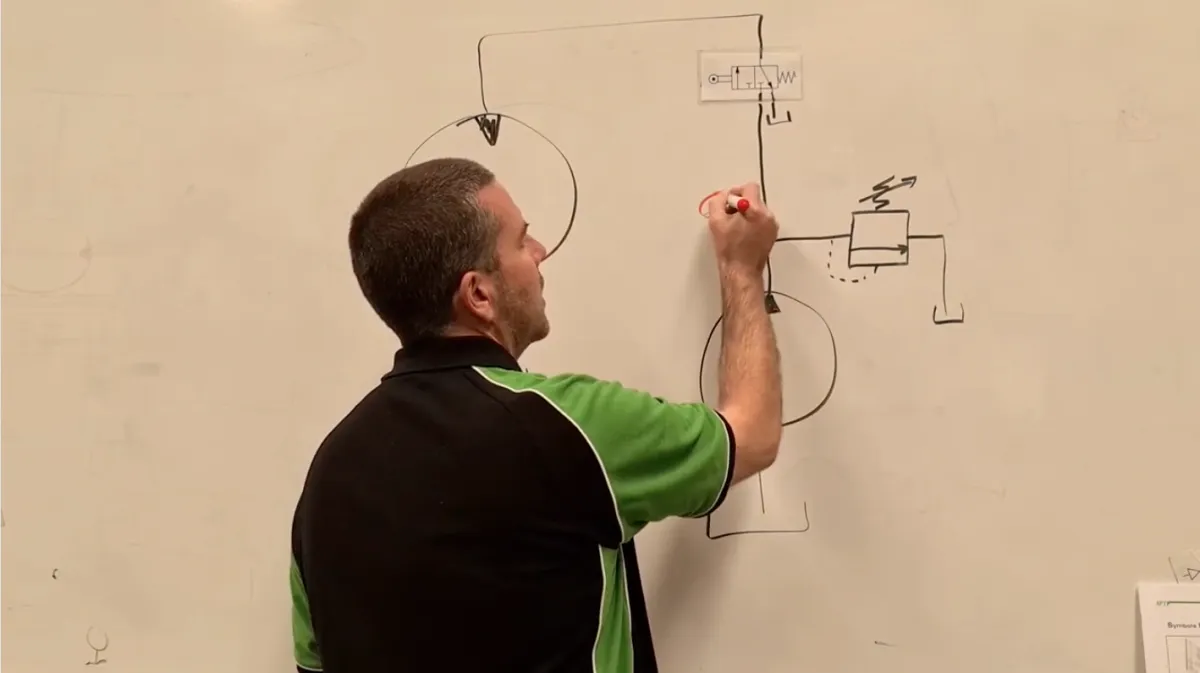

A Different Approach to Fluid Power Design: Start with a Simple Sketch

Learn the way Kyle teaches industry leaders - bite-sized, practical, and always focused on understanding the 'why

Why Our Approach Works?

Real-World Focus

Apply each lesson to your current projects

Learn from actual system failures and successes

Get feedback from industry experts

Build confidence through understanding, not memorisation

Start Simple, Build Confidence

Begin with Kyle's signature sketching method

Break down complex systems into manageable parts

Build understanding through practical application

No overwhelming theory - just what works in the real world

Bite-Sized Learning That Sticks

1-2 hours per session, broken into focused chunks

Take time to apply concepts to your real projects

Learn at your own pace - no rushing

Connect with others in our support group for guidance

QUESTIONS?

WELCOME ALWAYS!

Get support through our private group, where Kyle and the team actively engage with students. Because sometimes, you just need to bounce ideas off someone who gets it

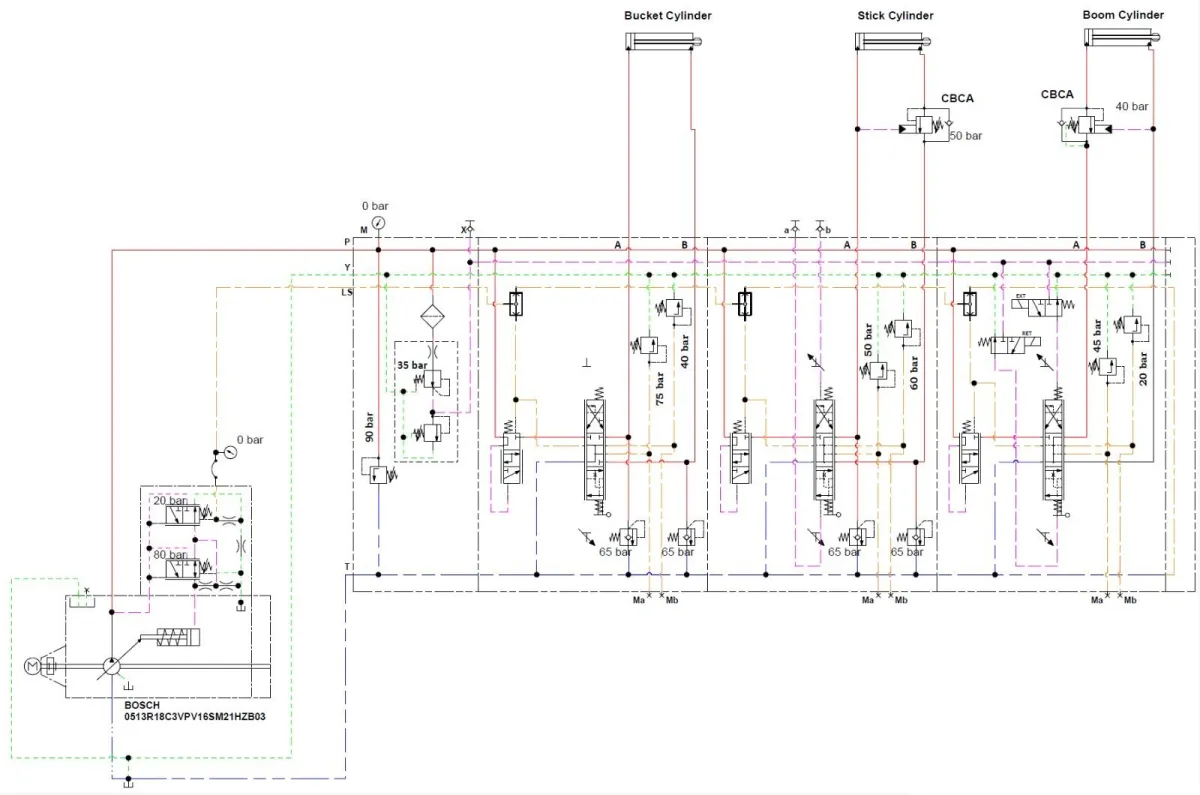

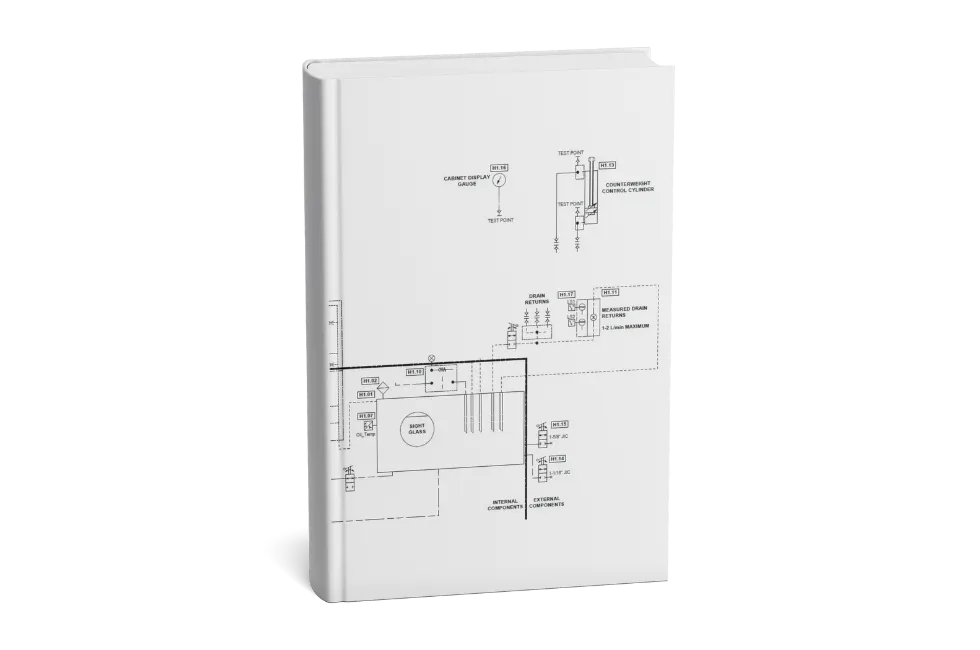

EXAMPLE OF SKETCH TO SYSTEM TRANSFORMATION

What You'll Master in Our Comprehensive Program

Engineering Principles That Work

Transform complex theories into practical understanding

Master force and pressure relationships

Calculate system requirements with confidence

Apply fundamental principles to real designs

Power System Mastery

Size motors and pumps correctly every time

Understand sequence operations thoroughly

Design efficient power units

Create systems that perform reliably

Component Selection & Sizing

Choose the right components for your application

Master proper sizing techniques

Understand filtration requirements

Optimize system performance

Control System Design

Design effective control valve systems

Implement proper motion control

Create safe, reliable operations

Troubleshoot with confidence"

Real-World Implementation

Every concept is taught through practical application:

Work on actual industry examples

Apply learning to your current projects

Practice with our proven design templates

Get feedback on your work

Confident Decision-Making:

Select components with certainty

Calculate system requirements accurately

Validate design choices

Communicate effectively with suppliers

Key Learning Outcomes:

Fluid power design principles

Speed and force calculations

Hose and component sizing

Pressure limitation expertise

System assembly knowledge

Power requirements mastery

Professional documentation skills

Progress pathway diagram

Skill development timeline

Application examples

Success indicators

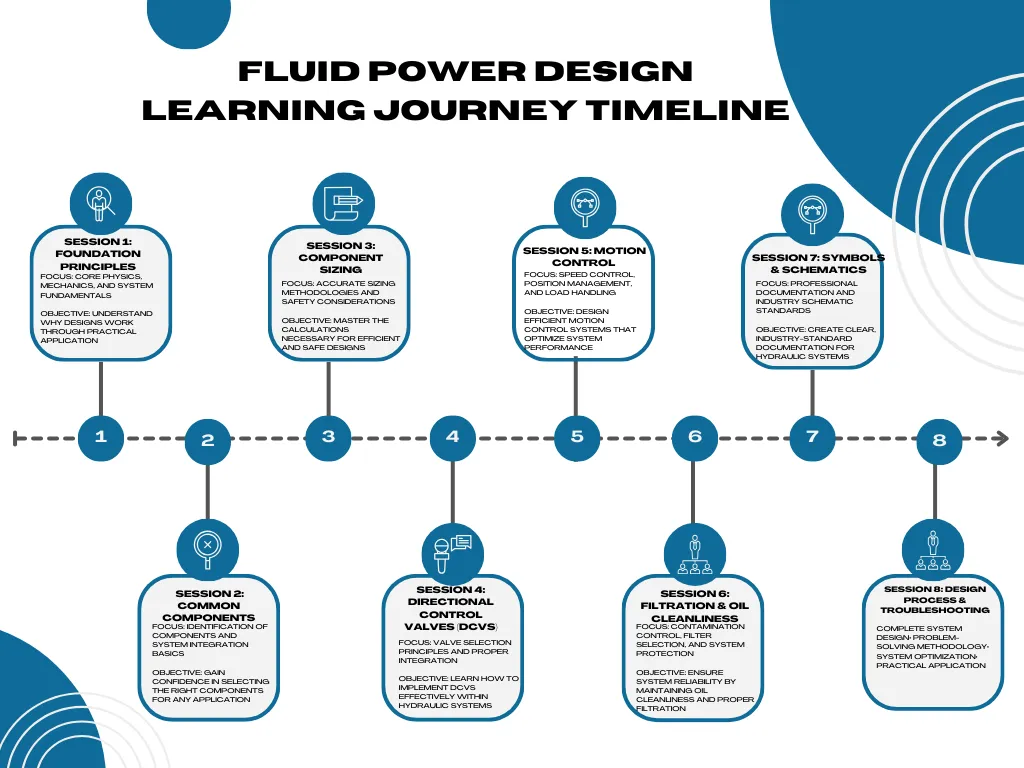

Your 8-Session Journey to Fluid Power Design Mastery

Time Commitment:

Each session is approximately 10 hours, broken into manageable segments

Session 1: Foundation Principles

• Core physics and mechanics

• System fundamentals

• Practical applications

• Understanding the 'why' behind designs

Learning Outcome:

Apply foundation principles

to real systems

Session 2: Common Components

• Component identification

• System integration basics

• Selection criteria

• Application considerations

Learning Outcome: Confidently identify and select components

Session 3: Component Sizing

• Accurate sizing methodology

• System implementation

• Safety considerations

• Practical calculations

Learning Outcome:

Size components correctly for any application

Session 4: Directional Control Valves (DCVs)

• Valve selection principles

• System integration

• Sizing methodology

• Application techniques

Learning Outcome:

Master DCV selection and implementation

Session 5: Motion Control

• Speed control principles

• Position management

• Load handling

• System optimization

Learning Outcome:

Design efficient motion control systems

TOPIC 4: Hoses & Pipes

Your design needs something to connect it all together and choosing the right hose can make all of the difference. This is our last component based topic and will see you making the design choices you need to get your system operational. We’ll talk through the potential pitfalls of different choices so that you can make a decision that is best for your end product.

TOPIC 5: The Final Design And Troubleshooting

We’ll be putting pen to paper and creating the schematics of your final design in these sessions. But what if after all of this work you still run into a problem? Even the most experienced hydraulics professionals can make mistakes and that is why it is important to understand the role of troubleshooting in the design process. We’ll work on troubleshooting any problems that you come across so that you can tackle them early and still have that push-button start that you’ve always dreamed of.

Session 6: Filtration & Oil Cleanliness

• Contamination control

• Filter selection

• System protection

• Maintenance considerations

Learning Outcome:

Maintain system cleanliness and reliability

Session 7: Symbols & Schematics

• Professional documentation

• Industry standards

• Clear communication

• System representation

Learning Outcome:

Create professional system documentation

Session 8: Design Process & Troubleshooting

• Complete system design• Problem-solving methodology• System optimization• Practical application

Learning Outcome: Design complete systems with confidence

Learning Support:

Self-paced modules within each session

Practical exercises using real equipment

Interactive discussions

Project application opportunities

Design template implementation

Delivery Method:

Online access to all materials

Flexible completion timeline

Support group access

Self-check evaluations

Comprehensive documentation templates

What Industry Leaders Say About Our Approach

Industry Implementation

"Kyle's design template approach transformed how our team handles hydraulic systems. We've cut design time by 30% and virtually eliminated basic design errors."

-

-Senior Engineer, Caterpillar

Practical Application

"The step-by-step template made it simple to understand complex systems. Now I can confidently size components and create professional documentation."

-Maintenance Supervisor, BHP

Technical Excellence

"This course bridges the gap between theory and practice perfectly. The design template is now our standard for all new systems."

-Systems Designer, Komatsu

Supply & Service Excellence

"Kyle's design template has become essential for our service team. We're now able to optimize systems during repairs and provide better solutions to our customers."

-Operations Manager, Hydraulic Service Provider

Industry Implementation

"The systematic approach to design has transformed how we specify and supply components. Our customers appreciate our more detailed, professional documentation."

-Technical Director, Hydraulic Supply Company

Practical Application

"This course gave our maintenance team the confidence to not just repair, but improve systems. The design template is now our standard for system upgrades."

-Workshop Manager, Hydraulic Repair Specialist

Technical Excellence

"We've implemented Kyle's design principles across our entire operation - from component selection to system optimization. It's improved our service quality significantly."

-Senior Engineer, Mining Services

Supply & Service Excellence

"Kyle's design template has become essential for our service team. We're now able to optimize systems during repairs and provide better solutions to our customers."

-Operations Manager, Hydraulic Service Provider

What Industry Professionals Say About Our Approach

Mobile Equipment

"Kyle's design template revolutionized how we approach hydraulic systems in our mobile equipment. The high power-to-weight ratio calculations are spot on."

-Fleet Manager, Construction Company

Manufacturing & Production

"Understanding overload protection through hydraulic systems has improved our production line safety significantly. The course paid for itself in the first month."

-Production Engineer, Manufacturing Plant

Supply & Service Excellence

"We've transformed from parts suppliers to solution providers. Now we can confidently help customers optimize their systems using Kyle's methodology."

-Technical Director, Hydraulic Supply Company

Material Handling

"The systematic approach to designing lift systems, especially understanding load holding requirements, has been invaluable for our operations."

-Systems Designer, Materials Handling Equipment

Agriculture & Irrigation

"Kyle's practical approach to hydraulic system design has helped us create more efficient irrigation systems with better pressure control."

-Project Manager, Agricultural Systems

Mining & Resources

"The course's focus on contamination control and system protection has significantly improved our underground equipment reliability."

-Maintenance Supervisor, Mining Operations

Industrial Automation

"Understanding fluid power principles has enhanced our automation solutions, especially in high-precision applications."

-Controls Engineer, Automation Company

Marine & Offshore

"The course's coverage of fluid selection and system protection has been crucial for our marine applications."

-Marine Engineer, Offshore Services

Industry Impact

Where Our Graduates Excel:

Hydraulic supply and repair companies

Manufacturing and production

Marine and offshore

Mining and resources

Agricultural equipment

Industrial automation

Process industry

Construction and earthmoving

Material handling systems

Mobile equipment

Engineering consultancies

Real Business Outcomes:

Improved system efficiency

Better component selection

Enhanced safety protocols

Better component selection accuracy

Reduced maintenance costs

More accurate troubleshooting

Professional documentation

Confident design decisions

Better customer solutions

Reduced warranty claims

More repeat customers

Higher customer satisfaction

improved first-time fix rates

Enhanced technical confidence

Improved documentation skills

Better problem-solving abilities

Stronger customer relationships

15+ years industry experience

Located at Mayfield West, NSW

Supporting local and national businesses

Active across multiple sectors

Active in current projects

The KAPEC Difference

Teaching Philosophy

"What you tolerate gets repeated"

Build from fundamentals

Focus on practical application

Learn through real examples

Create reliable solutions

Complete Learning Ecosystem

KAPEC's design expertise and mentoring

APT's hands-on training facilities

Real industry case studies

Active project support

Dual Learning Approach

For Practical Experience:

Hands-on component understanding

Real system troubleshooting

Practical design applications

Direct connection to maintenance knowledge

The KAPEC Difference

For Technical Knowledge:

Systematic design approach

Component selection methodology

System optimization

Professional documentation

Real-World Expertise:

Active involvement in industry designs

Current project experience

Practical problem-solving

Direct industry applications

Beyond Just Training:

Design template system

Professional documentation standards

Industry-proven approach

Ongoing support network

Real project application

Support Structure:

Project guidance when needed

Access to extensive industry experience

Connection to hands-on training

Professional network

Continuous learning pathway

Your Complete Learning Journey

Course Structure

• 8 comprehensive sessions

• Total course duration: approximately 10 hours

• Self-paced learning format

• Project application opportunities

• Interactive support system

• One-time payment

• Instant access to all materials

• Lifetime access to content

A Quick Snapshot

Guided program breaking down everything you need to know about Fluid Power Design to go from beginner to understanding & building better systems in just 9 sessions.

Timeframe

12 weeks recommended (however, the coursework is entirely self-paced so take as much time as you need to fully understand the concepts)

Delivery

Online Tutorials (recorded and loaded into our platform so you can review the content as much as you need)

Assessment

Projects + Practical designs based on the systems that you currently use Investment

End Result

The ability to design basic fluid power systems and create safer and more efficient systems to be used on your worksite. More confidence in your ability to create working designs, with a push button start, even without another set of eyes looking over your work because you've been made aware of the possible pitfalls of designs and all the most important info to create designs that not only work but are the best solution to your problem.

How Will it Work?

"Hydraulic System Design Course for Engineers and Technicians"

This course will be helping engineers, workshop managers and technical assistants who want to gain further knowledge and confidence in how to design hydraulic systems to best suit their work environment now and into the future. With lots happening in the hydraulics industry and the need to keep up with advancing technologies, we’ll run through both design basics and cover topics that will help you design something more sophisticated in the future, but for now let’s keep it simple.

"Interactive Hydraulic Design Modules with Expert Guidance"

Each online module will be led by hydraulicSub-Headlines expert Kyle Probert and while working through each topic you will be given an activity or project that will help you process what you’ve learned so that you can apply it to the current project you are working on. The modules are laid out in a way that walks you through the process of designing each element required for a fully functional system. Once you’ve completed the activity you can then drop your finished element into the group for feedback so not only are you taking this opportunity to learn but also to use your expertise to help others.

"Hands-On Hydraulic Design: Overcome Obstacles and Gain Confidence"

The biggest focus is on the actual design process itself and how we work through any obstacles that present themselves. So, if you want to gain the confidence and competence you need to make design decisions, to troubleshoot problems, and create custom solutions then you’re in the right place! There is nothing else like this course available in Australia.

Who Is It For?

This is not a beginner friendly course and it is highly recommended that participants have experience working with hydraulics systems and are familiar with basic engineering concepts.

Common roles that would benefit from this course are hydraulic engineers, workshop managers, technical assistants, and others who regularly are required to design or optimise hydraulic systems in their work.

*This is not a nationally accredited course

Money-Back Guarantee

If you get stuck into the course and within 48 hours have decided that this isn't right for you, we'll give you your money back no questions asked. However, we do require that you at least complete the first 2 sessions within module 1 before you make your decision.

What's Included:

Session recordings

Foundation Learning Materials

Detailed course content

Reference materials

Professional documentation templates

Design calculation sheets

Real-World Application Tools

Practical design examples

Component sizing guides

System documentation templates

Troubleshooting frameworks

Hands-On Learning Focus

Apply to your current projects

Work through real examples

Practice calculations

Master documentation standards

Implement safety considerations

Support Resources

Private discussion group

Technical guidance

Project application support

Industry updates

Safety bulletins

Prerequisites:

Basic hydraulics exposure

Mechanical qualifications (trade/university) recommended

Access to computer for documentation

Commitment to learning

TODAY'S PRICE: $998

Learn from Someone Who Lives and Breathes Fluid Power Design

Kyle Probert

"What You Tolerate Gets Repeated"

That's why we focus on getting the foundations right. No copying old designs hoping they'll work. Instead, you'll understand the 'why' behind every decision, giving you the confidence to design systems that work exactly as intended.

Not Just Another Trainer

Kyle doesn't just teach hydraulics - he's in the field every day:

Solving complex design challenges

Investigating system failures

Optimizing existing systems

Mentoring industry professionals

Supporting major projects across Australia

Why Learn from Kyle?

Brings 20+ years of hands-on experience

Currently active in industry projects

Known for his systematic design approach

Masters the art of simplifying complex systems

Teaches from real-world experience, not just theory.

The "Sketch-to-Success" Approach

"I always start with a simple sketch. It's how I've helped companies like Caterpillar and BHP solve complex challenges, and it's how I'll teach you to master system design."

Industry Impact

Quiet advisor behind countless successful designs

Partner with APT Training for hands-on delivery

Trusted consultant to mining giants

Problem-solver for manufacturing leaders

Mentor to next-generation engineers

Teaching Philosophy

"Complex systems don't need complex solutions. They need systematic understanding."

Start with proper foundations

Build confidence through practice

Focus on both 'why' and 'how'

Learn from real mistakes

Master professional documentation

Real-World Expertise

System verification and validation

Incident investigation

Design optimization

Safety compliance

Professional mentoring

Based in Mayfield West, NSW, Kyle's influence extends across Australia through:hind countless successful designs

Direct project support

Industry partnerships

System design consultation

Training collaboration

Ongoing mentorship